Sobre a loja

Somos uma empresa de distribuição de produtos para Automação, Elétrica e Instrumentação industrial. Nossos produtos: Fonte de Alimentação, CLP, Inversor de Frequencia, Cabos, Reles, Conectores, Cortina de Segurança.

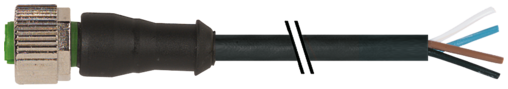

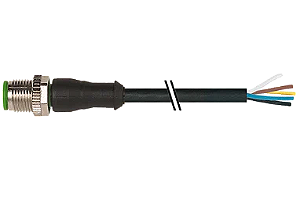

Cabo PUR M12 Fêmea Reto + Aberto 4P Preto 3 Metros 7000-12221-6240300

até

3x

de

R$ 25,93

sem juros

Comprar

Disponibilidade: Imediata

Aproveite! Restam apenas 2 unidades

-

- 1x de R$ 77,81 sem juros

- 2x de R$ 38,90 sem juros

- 3x de R$ 25,93 sem juros

-

- 1x de R$ 77,81 sem juros

- 2x de R$ 42,66

- 3x de R$ 28,85

- 4x de R$ 21,66

Dados Técnicos

| Cable length | 3 m |

|---|

Side 1

| Tightening torque | 0,6 Nm |

|---|---|

| Mounting method | inserted, screwed |

| Coating contact | gold plated |

| Family construction form | M12 |

| Thread | M12 x 1 |

| suitable for corrugated tube (internal Ø) | 10 mm |

| Cable outlet | straight |

| Coding | A |

| Material contact | Copper alloy |

| Material | PUR |

| No. of poles | 4 |

| Width across flats | SW13 |

| Degree of protection (EN IEC 60529) | IP65, IP66K, IP67 |

Side 2

| Stripping length (jacket) | 20 mm |

|---|---|

| Family construction form | free cable end |

Electrical data | Supply

| Operating voltage AC max. | 250 V |

|---|---|

| Operating voltage DC max. | 250 V |

| Current operating per contact max. | 4 A |

Diagnostics

| Status indication LED | no |

|---|

Installation | Connection

| Stripping length (jacket) | 20 mm |

|---|---|

| Mounting set | M12 x 1 |

| Gender | female |

Device protection | Electrical

| Degree of protection (EN IEC 60529) | IP65, IP67, IP66K |

|---|---|

| Additional condition protection degree | inserted, screwed |

| Pollution Degree | 3 |

| Rated surge voltage | 2,5 kV |

| Material group (IEC 60664-1) | I |

Mechanical data | Material data

| Coating locking | Nickeled |

|---|---|

| Coating of fitting | nickel plated |

| Locking material | Zinc die-casting |

| Material screw connection | Zinc die-casting |

Mechanical data | Mounting data

| Mounting method | inserted, screwed, Shaking protection |

|---|

Environmental characteristics | Climatic

| Operating temperature min. | -30 °C |

|---|---|

| Operating temperature max. | 85 °C |

| Additional condition temperature range | depending on cable quality |

Important installation notes

| Note on strain relief | Protect the connectors by suitable measures from mechanical loads, e.g. by the usage of cable ties. |

|---|---|

| Note on bending radius | Attention: Observe the permissible bending radii when laying cables, as the IP protection class can be endangered by excessive bending forces. |

Conformity

| Product standard | DIN EN 61076-2-101 (M12) |

|---|

Cable

| Cable identification | 624 |

|---|---|

| Cable Type | 2 (PUR/PVC) |

| Approval (cable) | UL (AWM-Style 20549/1731), CSA; CE conform |

| Cable weight [g/m] | 42,68 g |

| Material wire | Cu wire, bare |

| Resistor (core) | max. 57 Ω/km (20 °C) |

| Single wire Ø (core) | 0.1 mm |

| Construction (core) | 42× 0.1 mm (multi-strand wire class 6) |

| Diameter (core) | 4× 0.34 mm² |

| AWG | similar to AWG 22 |

| Material wire isolation | PVC |

| Material property wire insulation | CFC-, cadmium-, silicone- and lead-free |

| Shore hardness wire isolation | 43 ±5 D |

| Wire-Ø incl. isolation | 1.25 mm ±5% |

| Color/numbering of wires | br, bk, bl, wh |

| Stranding combination | 4 wires twisted |

| Shield | no |

| Material jacket | PUR/PVC |

| Material property (jacket) | CFC-, halogen-, cadmium-, silicone- and lead-free, matt, low-adhesion, machine easy to process, abrasion-resistant, hydrolysis and microbial resistant |

| Shore hardness jacket | 80 ±5 A (PVC-under jacket); 85 ±5 A (PUR-jacket) |

| Outer-Ø (jacket) | 4.6 mm ±5% |

| Color jacket | black |

| chemical resistance | good resistance to oil, gasoline and chemicals |

| Nominal voltage | UL 300 V AC |

| Test voltage | 2000 V AC |

| Current load capacity | to DIN VDE 0298-4 |

| Temperature range (fixed) | -30...+80 °C |

| Temperature range (mobile) | -5...+80 °C |

| Bending radius (fixed) | 10× outer Ø |

| Bending radius (dynamic) | 15× outer Ø |

| No. of bending cycles (C-track) | max. 2 Mio. (25 °C) |

| Travel speed (C-track) | max. 3.3 m/s |

| Acceleration (C-track) | max. 5 m/s² |

Produtos relacionados

-

Cabo Pur M12 Macho Reto 4P Cinza 10 Metros 7000-12021-2241000

Cabo Pur M12 Macho Reto 4P Cinza 10 Metros 7000-12021-2241000R$ 99,10R$ 74,73até 3x de R$ 24,91 sem juros25% Desconto -

Cabo Pur M12 Macho Reto 4P Cinza 2 metros 7000-40021-2240200 Murrelektronik

Cabo Pur M12 Macho Reto 4P Cinza 2 metros 7000-40021-2240200 MurrelektronikR$ 159,84R$ 114,67até 5x de R$ 22,93 sem juros28% Desconto -

Cabo Pur M12 Macho Reto 6P Verde 15 Metros 7000-46041-8021500 Murrelektronik

Cabo Pur M12 Macho Reto 6P Verde 15 Metros 7000-46041-8021500 MurrelektronikR$ 1.690,00R$ 1.301,49até 10x de R$ 130,14 sem juros23% Desconto -

Cabo Pur M12 Macho Reto 5P Preto 3 Metros 7000-12041-6350300 Murrelektronik

Cabo Pur M12 Macho Reto 5P Preto 3 Metros 7000-12041-6350300 MurrelektronikR$ 115,95R$ 93,86até 4x de R$ 23,46 sem juros19% Desconto

-

Categorias

Conteúdo

Sobre a loja

Somos uma empresa de distribuição de produtos para Automação, Elétrica e Instrumentação industrial. Nossos produtos: Fonte de Alimentação, CLP, Inversor de Frequencia, Cabos, Reles, Conectores, Cortina de Segurança.